The suggested reorder number can be used to pre-fill purchase orders. This article explains how this number is selected.

Basically, the suggested reorder looks at the sales from the last 6 months of all parts.

Per part, it takes the total number of sales for the last month (month01) * .7 + month02 * .2 + month03 * .1 + month04 * .07 + month05 * .02 + month06 * .01 and divides that number by 4.3 to figure the Average Weekly Sales (AWS) per part.

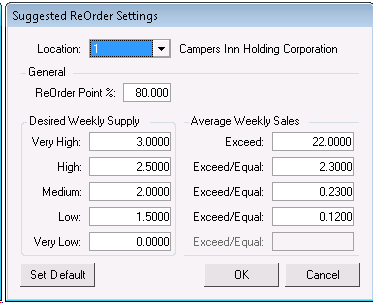

Then, based on the part’s AWS:

If the number is > 22 it sets the Mean Inventory Level (MIL) to (3 + (the average lead time in days / 7)) * AWS.

If the number is >= 2.3 and <=22 it sets the MIL to (2.5 + (the average lead time in days / 7)) * AWS

etc.

The part's temporary MIL is set to the higher of the calculated MIL or the parts Minimum. This is the highest level of inventory it thinks we should be at.

The part's Reorder Point (ROP) is set to the temp MIL * .80 (the ReOrder Point %). This is the minimum level of inventory it has calculated. This number is calculated as a suggested minimum but never used.

The part's order quantity is then figured as the (MIL - (TOH - TOA) - TOO)/ packaging ratio. If that number is < 0 it is set to 0. The quantity of the parts already on the order list plus any that are waiting to be returned are also subtracted out of this.

It's capped to not go over the part's Max unless the Max is 0.

All parts with an order quantity >0 are added to the suggested order list.

Examples:

Example 1:

Part X1 has sales of 160, 201,213,244,224,174 for the last 6 months, 98 TOH, 20 TOO, 6 TOA, Min/Max of 20/140, PackRatio of 1 and Leadtime of 1 day.

AWS=(112+40+21.3+17.08+4.48+1.74)/4.3=45.72

That’s >22 so MIL=(3+ (1/7))*45.72=143.69

MIL=143.69 and the ROP of 114.95

(143.69 - (98-6) -20)/1=31

The Order Quantity should be 31 but because of the part's max it will order 28.

Example 2:

Part A51 has sales of 14,10,9,0,0,1 for the last 6 months, 1 TOH, 0 TOO, 1 TOA, Min/Max of 0/0, PackRatio of 1 and Leadtime of 1 day.

AWS=2.97 if my calcs are correct

That’s >2.3 so MIL=7.56 and the ROP of 6.05

The Order Quantity will be 7

Example 3:

Part Z6 has sales of 14,22,24,25,29,30 for the last 6 months, 7 TOH, 20 TOO, 0 TOA, Min/Max of 4/0, PackRatio of 1 and Leadtime of 4 days.

AWS=4.47 if my calcs are correct

That’s >2.3 so MIL=11.81 and the ROP of 9.45

The Order Quantity will be 0